Improve performance in severe service liquid applications while maintaining valve efficiency and increased safety.

Cavitation is the formation and collapse of vapor bubbles (cavities) in liquid flow streams caused by changes in pressure and velocity. There are three primary negative side effects of uncontrolled cavitation in control valves: excessive vibration, equipment damage and deterioration of flow control.

One more simple step: Sign up for this exclusive webinar

Innovative Control Valve Anti-Cavitation Solutions to Protect Critical Process Equipment and Maximize Plant Availability:

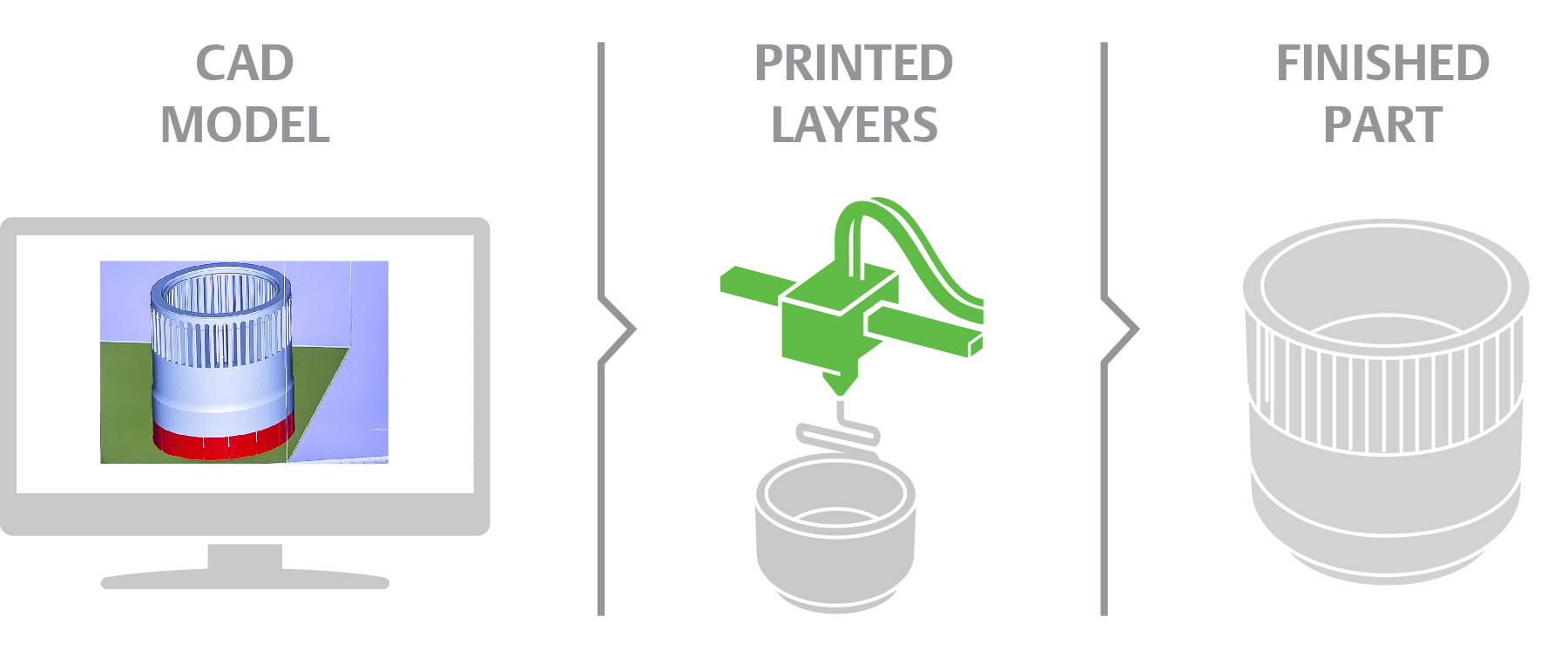

Using additive manufacturing to accelerate new product development

Boundless Design Potential

With additive technologies, intricate geometries no longer mean complicated or time-consuming build processes. By adding materials layer by layer, the manufacturing process becomes simpler, faster, and results in less material waste. It also allows us to broaden our design potential in order to solve more complex problems in new ways.

Rapid Prototyping

Using additive manufacturing, we're able to create parts in-house, so that design iterations can be tested, evaluated, and adjusted much faster and with less scrap than before. With the ability to get the most ideal version of the product to market quickly, we can address your process issues before they are compounded.

The products at the forefront of technology

Fisher™ Vee-Ball™ Rotary Control Valves are now available with Cavitrol™ Hex Anti-Cavitation Trim to reduce or eliminate vibration caused by cavitation.

Cavitrol™ Hex trim is available on Fisher V150, V200, V300 and the all-new CV500 rotary control valves. It can be easily retrofitted into previously installed Vee-Ball™ valves after minimal modifications to the valve body. The trim option is available on Vee-Ball valves in sizes NPS 4 through 12, providing high capacity for gas, steam and liquids. To meet specific application requirements, a variety of metal and soft ball seal materials are available.

Cavitrol™ Hex trim will not affect valve shutoff or valve temperature limits and does not influence the primary ball/seal interface.

Proven Results

- Cavitation protection on a rotary valve

- Customer achieved OPEX savings up to 50% by avoiding major piping modification and using rotary valve with anti-cavitation trim instead of globe valve with anti-cavitation trim

- Aided in ensuring process continuity and plant reliability.

The Severe Service App

Expertise at your fingertips

The Severe Service app is available for iOS and Android devices. Download it from the App Store or Google Play.

Emerson's Severe Service app is developed for process control engineers in need of quick and easy control valve diagnosis and maintenance for the most difficult installations within process plants.

Features of the app include instant access to Fisher control valve sizing tool, severe service control valve diagnosis information, a large technical library and a severe service industry application library to keep users up-to-speed on severe service topics with educational videos and reference collateral.

Severe service control valves are used in the most difficult installations within a plant and can fall victim to common issues such as cavitation erosion, high pressure, and other environmental challenges. The Severe Service app can help maximize the longevity of these critical assets so end users get the most from their investments while protecting employees, the environment and other plant assets.

Learn about valve cavitation and how damage can be reduced or prevented:

What is Valve Cavitation?

Fisher™ Cavitrol™ Hex Trim Eliminates Cavitation