Better Scope and Schedule Compliance with Plantweb™

Plan for a Better Return for Your Turnarounds

Turnarounds play a critical role in a plant's life cycle. Poor planning can result in unidentified issues with critical assets or overlooked processes. Insufficient workmanship can cause delayed startup and, even worse, safety and environmental mishaps.

It's time for you to repair, replace and upgrade your key assets to maximize your plant's true potential.

What's Your Opportunity?

Using Emerson's proven process for scheduling and prioritizing services, we can help you evaluate key performance indicators and asset health to develop a maintenance plan that can maximize your return on investment and reduce risk.

- Get assistance from start to finish for all of your valves, actuators, and regulators.

- Create a quantifiable and detailed work scope with asset monitoring and advanced diagnostic analysis.

- Prepare maintenance events with in-depth scoping, scheduling, and parts and resource planning.

- Optimize plant turnaround safety and efficiency utilizing digital tools.

Smart and Digitally Transformed Shutdowns, Turnarounds and Outages

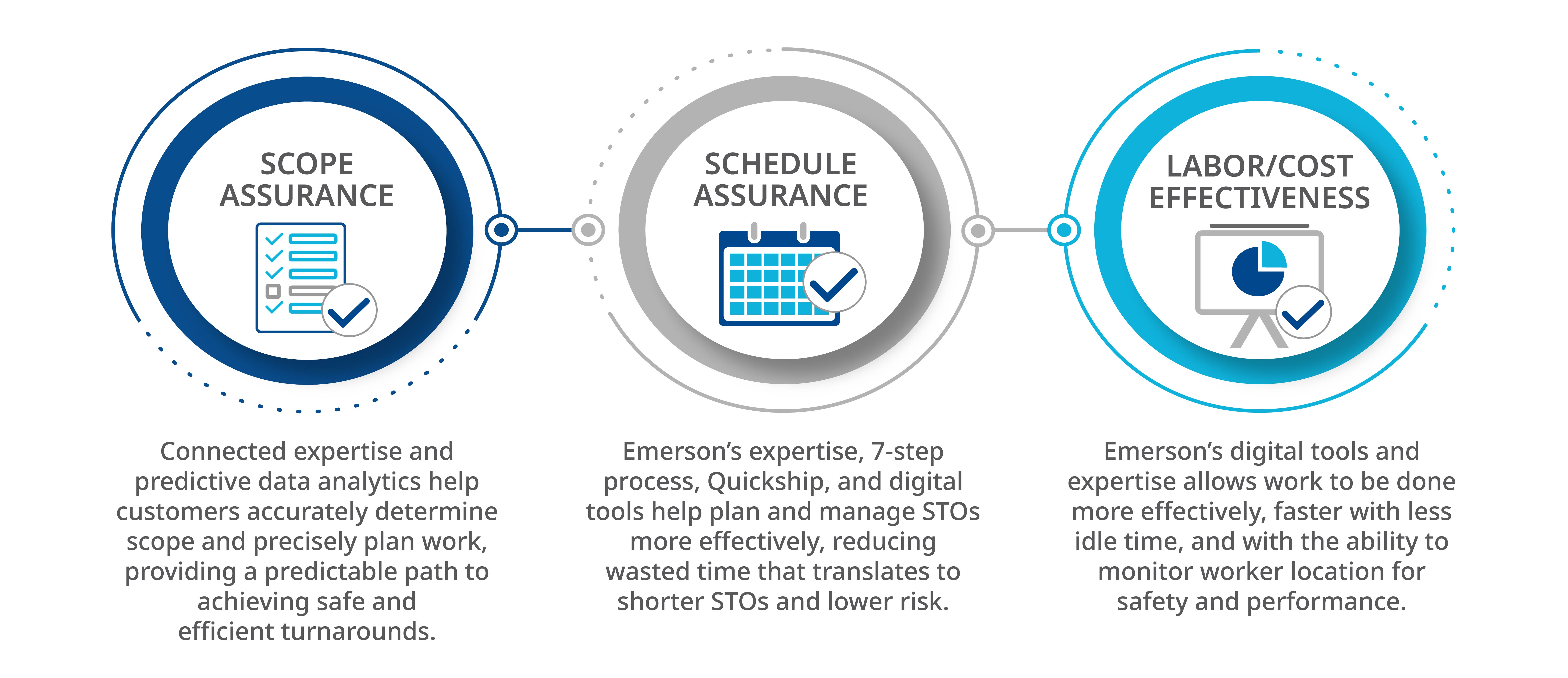

With Emerson's proven turnaround process, you'll be assured that planned maintenance is executed smoothly and efficiently, in the shortest amount of time:

- Predictive Diagnostics with ValveLink™ check degradation of asset performance and view trends over time with online or offline diagnostics.

- Valve Condition Monitoring services uses predictive diagnostics and data analytics technology to generate valuable information about process equipment and aid in better capability planning for critical plant assets.

- Digital Walkdown App provides an immediately accessible electronic record of field equipment, including health ratings that help prioritize work scope. The digitally transformed walk-downs help mitigate unnecessary costs while increasing scope and schedule assurance for better parts and spare management.

- Preventative Diagnostics with FlowScanner™ and valve seat leak detection tool gather offline data to help you understand how your assets are performing.

- Asset Management Tags store and retrieve critical information about an asset’s construction, repair history, replacement parts, and diagnostic data.

Download Free Case Studies

Digital Transformation of Shutdowns, Turnaround & Outages

Emerson's Connected Services for Valves - Using Data-Power Insights to Optimize Plant Throughput