Download This White Paper to Learn More About Mining Applications with Edge Control

Data available at the operational edge is now easily accessible.

Mining, like many other industrial sectors, generates large volumes of data. Much of the initial IIoT discourse focused on cloud computing, which meant that large quantities of raw data would be dispatched to cloud-based data lakes, analyzed and used in optimization algorithms to drive real-time decision making.

New systems can be natively designed and built to take advantage of edge automation, and current systems can be retrofitted with edge controllers installed in parallel with existing automation to obtain the most important data from legacy hardware and newer IIoT devices.

This white paper explores how edge automation plays a foundational role for applying digital transformation in the mining and metals industries.

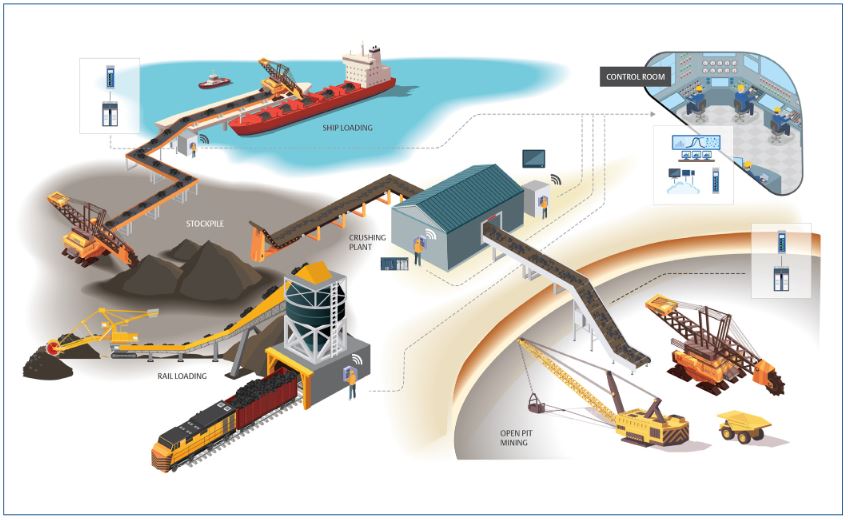

Many aspects of mining operations require some level of automation, and nearly every area creates data useful for analysis and operation.

PLCs play an important role in almost every area and may include local human machine interfaces (HMIs). Remote terminal units (RTUs) are also widely used, providing some functionality similar to PLCs and adding remote connectivity features. Increasingly, systems incorporate intelligent field devices like variable frequency drives (VFDs) that can supply extensive operational and diagnostic data. Larger processing areas may rely on a distributed control system (DCS), and plantwide operations may be monitored by a supervisory control and data acquisition (SCADA) system.

General Information can also be found under: