Effectively manage boil-off gas to avoid the environmental impact of flaring or disposal.

LNG Storage, Jetty Loading, and Boil-Off Gas Solutions

Usually, two or more above-ground tanks are installed for receiving and storing LNG. During normal operation, boil-off gas (BOG) is produced in the storage tanks and LNG lines by heat transfer from the surroundings. It is compressed and liquefied in a recondenser. This process helps to avoid flaring or venting and to minimize the environmental impact of the facility.

What's your opportunity?

- Recover boil-off gas

- Detect gas leaks

- Reduce the total installed cost of loading arms

- Minimize valuable product loss

Featured LNG Storage, Jetty Loading and Boil-Off Gas Solutions

Protect the compressor from damaging surge events with quick and accurate valve response to immediately recycle the discharge flow.

- The proper valve, actuator, and accessories can help increase compressor throughput, reliability, and efficiency as well as plant uptime

Minimize the total installed cost of loading arms with zero leakage cryogenic valves optimized for space and weight.

- A c-shaped ball reduces top flange diameter by 40%

- Up to 30% weight reduction versus traditional designs

- Compact, reliable, robust automation

Protect the compressor from damaging surge events with quick and accurate valve response to immediately recycle the discharge flow.

- The proper valve, actuator, and accessories can help increase compressor throughput, reliability, and efficiency as well as plant uptime

Packaged with AEV and Vanessa Automated, Welded Cryogenic Valves – Ensure safe, zero leakage shutoff in challenging jetty operations including isolation, flow modulation, and emergency shutdown.

- Minimize product loss and emissions with welded, ultra-low emission designs

- Trapped cavity risk eliminated

- Top entry design for in-line maintenance

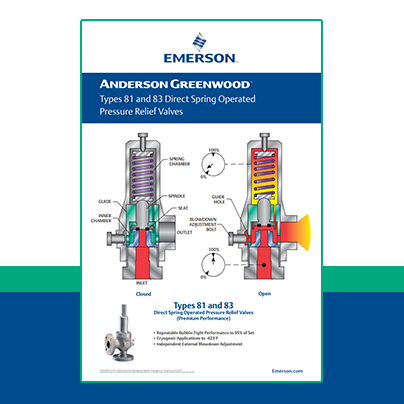

Protect the LNG storage tank from overpressure and vacuum scenarios while eliminating leakage during operation.

- Leading relief capacity per size

- Minimize the size or number of valves required for adequate protection

Protect against vapor ignition by reducing the temperature and momentum of a flame.

- Designed for unstable detonation

- Larger flame channels for lower pressure drop and less frequent maintenance

- The range covers both unconfined and confined applications and gas groups B, C, and D

Protect piping and equipment from thermal expansion due to the warming of the cryogenic LNG.

- Bubble tight seats and true pop action eliminate the risk of freezing

- Sized for thermal relief to minimize product loss

- Withstands full cryogenic temperatures

Inject LNG into the boil-off gas to cool it.

- Wide range of Kv capacities

- Dimensions to meet gas line size requirements

- Fine atomization for fast evaporation to minimize liquid accumulation in the suction drum

LNG Solutions

Manage LNG production by maximizing the liquefaction compressor discharge pressure to the limit.