Automotive

Components & Vehicle Systems

Fabrication & Assembly

Fuel Dispensing

Tires

Other

Chemical

Agrichemicals

Industrial Gas

Inorganic Bulk

Petrochemical

Polymers

Specialty Chemicals

Other

Downstream Hydrocarbons

Petrochemical

Refining

Terminals & Logistics

Other

Food & Beverage

Alcohol Beverage Processing

Brewing

Canned/Frozen

CBD/Cannabis

Dairy

Flavors

Fresh Foods

Grains

Meats

Oils

Packaging

Pet Food

Ready to Drink Beverages

Snacks/Prepared Foods

Spirits

Sugar

Winemaking

Other

Industrial Energy & Onsite Utilities

Boilers & Combustion Processes

Energy Management

Steam Header

Steam Traps

Other

Life Sciences

Biotechnology

Cell/Gene Therapy Manufacturing

Fill/Finish

Laboratories

Large Molecule Upstream

Large Molecule Downstream

Packaging

Pharmaceutical

Small Molecule Upstream

Small Molecule Downstream

Utilities

Other

Manufacturing

Marine

Chartering

Classification Societies

Equipment Manufacturer

Reselling / Distributing

Ship Building

Ship Management / Ship Operation

Service and Maintenance

Other

Medical

Medical Devices

Medical Diagnostics

Other

Mining, Minerals & Metals

Classification

Conveying

Crushing

Grinding

Other

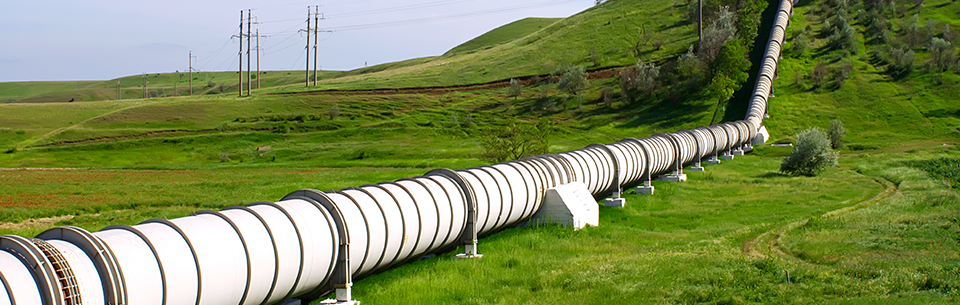

Oil & Gas

Conventional

Exploration & Production

Gas Processing & LNG

Oilfield Services

Transportation & Storage

Unconventional

Other

Packaging

Primary Packaging

Secondary Packaging & Palletizing

Other

Power Generation

Coal Power

Gas Power

Hydropower

Nuclear Power

Renewable Power Generation

Other

Pulp & Paper

Textiles

Water & Wastewater

Other